He aha te Tauwehenga Rere

Ko te Tauwehenga Rere, e mōhiotia ana ko Cv (Paerewa US/EU), Kv (Paerewa Ao), te uara-C rānei, he tawhā hangarau nui e tautuhi ana i te kaha rere o ngā takirere ahumahi pēnei i ngā takirere whakahaere me ngā kaiwhakahaere.

Te Tautuhi i te Uara CV

Ko te takirere Cv te tauwehenga rere e tohu ana i te kaha o te takirere ki te tuku wai i raro i ngā āhuatanga motuhake. Ka ine i te tere rere o te wai, o te hau rānei mā roto i te takirere i te hekenga pēhanga kua hoatu. Ko ngā uara Cv teitei ake e tohu ana i te kaha rere nui ake.

He aha te Cv (Uara Pūmanawa)

Ka ine te Valve Cv (Uara Pūmanawa) i te kaha rere, ā, ka tatauhia i raro i ngā tikanga whakamātautau paerewa:

• Tuwhera katoa te takirere

• Te hekenga pēhanga (ΔP) o te 1 psi puta noa i te takirere

• Wai: Wai i te 60°F (15.5°C)

• Te tere rere: karani US ia meneti (GPM)

Te Whakatuwheratanga o te Takirere me te Uara CV

He ariā motuhake te Cv/Kv me te whakatuwheratanga o te takirere (%):

• Whakamāramatanga Kv (Paerewa Haina):Te tere rere i roto i te m³/h ina ΔP = 100 kPa, te mātotoru wai = 1 g/cm³ (wai i te pāmahana rūma).

*Tauira:Ko te tikanga o te Kv=50 he 50 m³/h te rere i te 100 kPa ΔP.*

• Ōrau Whakatuwheratanga:Te tūnga o te mono/kōpae takirere (0% = kua kati, 100% = kua tuwhera katoa).

Te Tātai i te CV me ngā Tono Matua

Ka pāngia te CV e te hoahoa o te takirere, te rahi, te rauemi, te tikanga rere, me ngā āhuatanga wai (te pāmahana, te pēhanga, te matotoru).

Ko te tātai matua ko:

Cv = Q / (√ΔP × √ρ)

Kei hea:

• Q= Te tere rere rōrahi

•ΔP= Te rerekētanga pēhanga

•ρ= Te mātotoru o te wai

Tahuritanga: Cv = 1.167 Kv

Te Tūranga i roto i te Kōwhiringa me te Hoahoa o te Takirere

Ka pā tika te CV ki te whai huatanga o te pūnaha whakahaere wai:

•Te whakatau i te rahi me te momo takirere tino pai mō ngā reiti rere ūnga

•Ka whakarite i te pumau o te pūnaha (hei tauira, ka ārai i te huringa papu i roto i te puna wai o te whare)

•He mea nui mō te arotau i te pūngao

Ngā Rerekētanga CV puta noa i ngā Momo Takirere

He rerekē te kaha o te rere i runga i te hoahoa o te takirere (i ahu mai ngā raraunga iNgā paerewa ASME/API/ISO):

| Momo Takirere | Ngā Āhuatanga Matua | Tauira CV (Paerewa FCI) |

|---|---|---|

Takirere Keti | Cv Waenga (DN100 ≈ 400); kāore i te pai te whakahaere; karohia te whakatuwheratanga <30% (mōrearea o te aueue e ai ki te ASME B16.34) | DN50: ~120 |

Takirere Pōro | Teitei Cv (1.8× ngā takirere kuaha); te whakahaere rere raina; API 6D e taunakitia ana mō ngā paipa | Pōro-V DN80: ≈375 |

Takirere Pūrerehua | He iti te utu mō ngā rahi nui; ±5% te tika (takitoru-whakawhitinga); he iti te pikinga rere >70% tuwhera | DN150 Angaanga: ~2000 |

Takirere Ao | Te ātete teitei (Cv ≈ 1/3 o ngā takirere pōro); te mana whakahaere tika (whakamahinga hauora/taiwhanga) | DN50: ~40 |

Ngā Tawhā Rere Matua me ngā Take Whakaawe

E toru ngā tawhā e tautuhia ana te mahi a te takirere (e ai ki te Fluid Controls Institute):

1. Uara CV:Te rere o te GPM i te 1 psi ΔP (hei tauira, te takirere pōro DN50 ≈ 210 vs. te takirere kēti ≈ 120).

2. Tauwehenga Ātete Rere (ξ):

•Takirere pūrerehua: ξ = 0.2–0.6

•Takirere porowhita: ξ = 3–5

Ngā Aratohu Kōwhiringa me ngā Whakaaroaro Hiranga

Whakatikatika i te Matotoru:

Tāpirihia ngā whakarea ki te Cv (hei tauira, te hinu mata: 0.7–0.9 i runga i te ISO 5208).

Ngā Takirere Atamai:

Te arotautanga CV wā-tūturu (hei tauira, te tūnga Emerson DVC6200).

Ngā Pūnaha Whakamātautau Tauwehenga Rere

Me whakahaere ngā tikanga whakamātautau nā te aro o te ine:

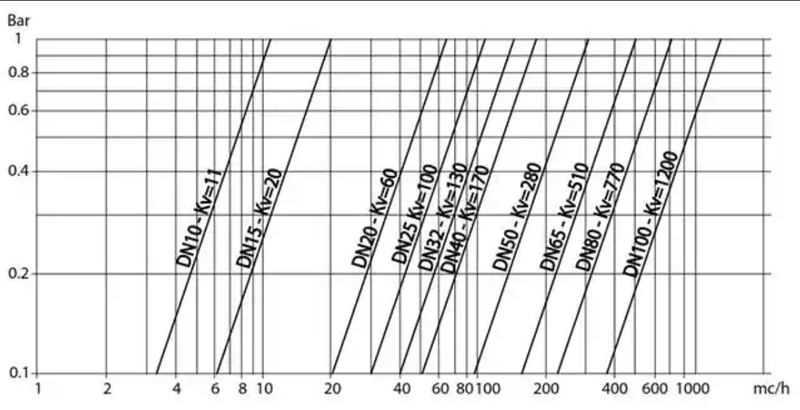

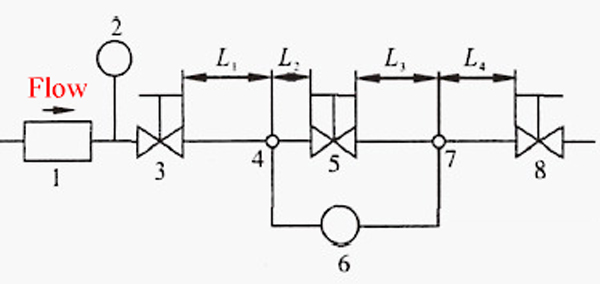

•Tatūnga (E ai ki te Pikitia 1):

Mita rere, inemahana, ngā takirere whakawhāiti, te takirere whakamātautau, te ine ΔP.

1. Mita rere 2. Inemahana 3. Reera whakatere o runga 4 me te 7. Ngā kōhao pato pēhanga 5. Reera whakamātautau 6. Pūrere ine rerekētanga pēhanga 8. Reera whakatere o raro

4. Ko te tawhiti i waenganui i te kōhao pato pēhanga me te takirere e rua ngā wā o te whānui o te paipa

7. Ko te tawhiti i waenganui i te kōhao pato pēhanga me te takirere he 6 ngā wā o te whānui o te paipa

•Ngā Mana Matua:

- Mā te takirere o runga e whakahaere te pēhanga tomo.

- Ka pupuri te takirere o raro i te pēhanga pumau (rahi noa > takirere whakamātautau hei whakarite kia puta te rere kōpikopikointakirere whakamātautau).

•Ngā Paerewa:

JB/T 5296-91 (Haina) vs. BS EN1267-1999 (EU).

•Ngā Take Matua:

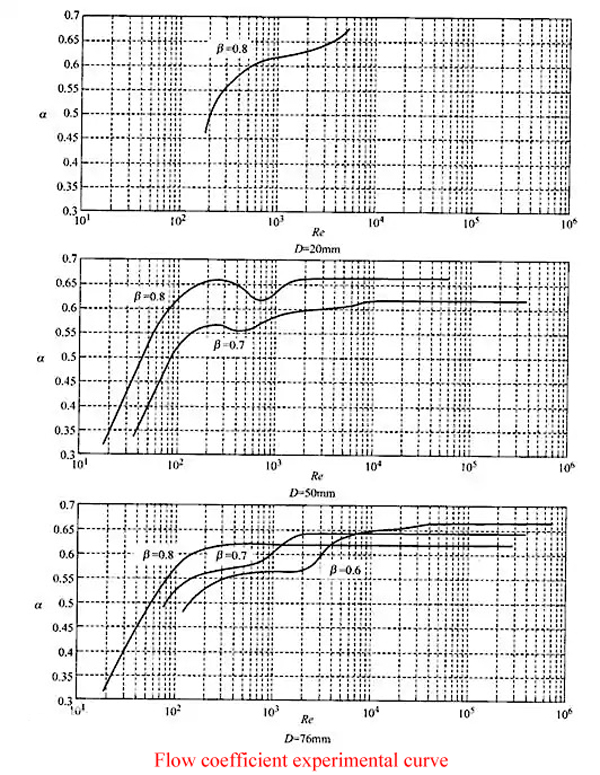

Te tauwāhi o ngā pūwero, te whirihoranga o ngā paipa, te tau Reynolds (wai), te tau Mach (hau).

Ngā Here me ngā Otinga Whakamātautau:

•Ngā takirere whakamātautau pūnaha o nāianei ≤DN600.

•Ngā takirere nui ake:Whakamahia te whakamātautau rere o te hau (kāore i te whakamāramahia i konei).

Te Pānga o te Tau Reynolds: E whakaū ana ngā raraunga whakamātautau he nui te pānga o te Tau Reynolds ki ngā hua o te whakamātautau.

Ngā Whakaaro Matua

•Ko te Cv/Kv te tohu o te kaha rere o te takirere i raro i ngā tikanga paerewa.

•He pānga nui tō te momo takirere, te rahi, me ngā āhuatanga o te wai ki te CV.

•Me piri pono ki ngā tikanga (JB/T 5296-91/BS EN1267) hei whakamātautau kia tika ai.

•Ka pā ngā whakatikatika ki te matotoru, te pāmahana, me te pēhanga.

(Nō ngā paerewa ASME/API/ISO me ngā pepa mā o te kaihanga takirere ngā raraunga katoa.)

Wā tuku: Hanuere-06-2025